Who Was First?

Relayless Reeds

Who invented the first relayless reed system? This question has two parts— first overall, and first to be offered commercially.

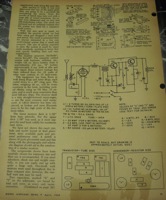

Resonant reed RC systems attained a remarkable degree of reliability in the 1950s. They dominated the industry for years, at least at its upper end. However, early reed systems contained banks of relays in addition to the reeds. The relays were bulky, heavy, vulnerable to engine vibration problems and required some cleaning or maintenance. Here, for example, is a comparison of a C.G. 8 channel relay reed receiver with a C.G. 10 channel relayless version. Although the relayless receiver has two additional channels of control, it is less than half the size and less than half the weight.

Forward thinking flyers and designers yearned for the day someone would liberate reeds from relays.

So who did it first?

Bonner Transmite

Commercially, it appears that Orbit, Bramco and other manufacturers had relayless reed receivers in 1960. The key was development of a relayless servo to make these receivers a commercial success. Based on preliminary research, the Bonner Transmite seems to have been the first.

At the 1960 Nationals, Bonner and Orbit both demonstrated preliminary models of relayless servos. In the Nov/Dec 1960 issue of Grid Leaks it was announced that “Bonner relayless is about due on the market.” The Bonner Transmite relayless servo probably became commercially available toward the end of 1960, or the beginning of 1961 (when the first ads were published).

But who was the first of all—even before relayless became commercially available?

It might have been Louie Scheel.

The Scheel/Oliver Tremac

Here is the landmark Model Airplane News article documenting an early achievement of relayless reeds by Louie Scheel and Ken Oliver. Although published in April, 1960, the system was flying in 1959. Another early relayless system was described in the May/June 60 edition of Grid Leaks, but this was cruder, with single transistor actuation and no self neutralizing. Good, but not really in the same league.

In addition to going relayless, Scheel went miniature. The incredibly small servos were possible only by rewinding and literally grinding down the Mighty Midget motor—the leading motor available back then.

To achieve this system in 1959, Scheel and Oliver had to learn, by trial and error, all of the electronics involved as well as metal forming and anodizing and electric motor design and construction. They even devised a logo, and taught themselves how to silk screen it onto the cases. You can see this in the article, “Tremac Control Systems”. How many have wondered what Tremac was, or stood for?

Here’s the answer, after nearly 50 years-- “Transistorized Rudder, Elevator, Motor & Aileron Control” .

Finishing touches like this logo and the anodized cases were done solely in pursuit of excellence; Scheel says they never intended to commercialize their invention.

Final Ingredient

Success did not come easily, or quickly. After many months and crashed planes, Scheel finally discovered the missing ingredient to make the system reliable. All it took was to paint the top of the fuselage white. It didn’t matter what type of plane was flown or what color scheme was used on other parts, so long as the top of the fuselage was white, as pictured in the article. Why?

Darker colors absorbed the sun’s energy and elevated the temperature inside to a level that overwhelmed the heat-sensitive germanium transistors. When this occurred, one or more of the aircraft’s control surfaces would freeze in full deflection and the plane would promptly crash. Once the fuselage top was painted white, the crashes stopped and the radio became quite reliable.

What a difference a paint job can make.