Special Exhibit:

Prototype Steeb Servos

(Click on any of the images on this page to see a larger version)

Steeb One

These are the first Don Steeb Inc. servos ever made:

Many RC systems in the late 50s and early 60s were named after the US space program with its historic achievements that enthralled the world (e.g. Space Control, Orbit, Astronics, Spacetron, Astroguide, Astron). The name for Steeb servos was inspired by the Atlas rocket famous for launching astronaut John Glenn, the first American to orbit the earth. In 1957, however, the Atlas rocket, was used for military payloads only; manned Space flight would not occur until the 1960s. Don Steeb was ahead of his time and his servos showed it. He took the first production run of servos with him to the 1958 Nationals. When the nation’s top flyers saw the obvious quality, they snapped up every one – his entire stock sold in 2 days without advertising.

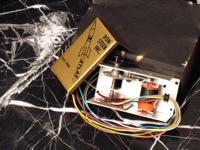

These 2 prototype servos were hand made by Don Steeb in 1957 to prove the viability of his servo design to financiers so he could obtain the necessary funding to launch his business. Here is an inside view of a prototype and for comparative purposes, the inside of the first production Atlases:

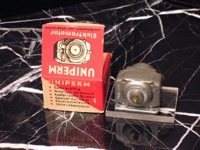

The main feature of the servos was the gray plastic-cased motor. This was made by Uniperm in Germany and was of a generally higher quality than other motors used in servos back then. Here is a never used Uniperm motor in its original box:

These servos were for multichannel reed operation since multi servos commanded a substantially higher price than single channel servos, increasing the odds that Steeb’s new company could succeed financially. Only later did Steeb introduce single channel servos.

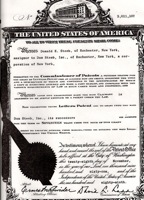

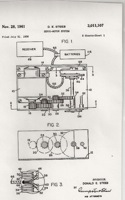

Note also that the case refers to patent pending. Steeb went through the trouble and expense of patenting these servos, something rarely done by RC manufacturers and actually received the patent from the US government on November 28, 1961. Here are the first and last pages of that patent, No. 3,011,107.

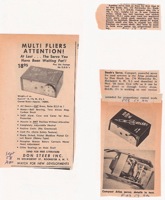

Here are the American Modeler new product reports on Don Steeb servos (Nov 58 and Feb 59) and the first advertisement (Sept 1958 AM):

In the December 1959 AM the following open letter from Steeb (announcing a price reduction from $18.95 to $14.95) and pictureless ad appeared:

Here’s how the ad looked with the new price (June 1961 MAN):

The June 1961 version was for the second generation servos; it was never changed and continued to run in AM through its January/February 1965 edition.

Don Steeb Inc. was incorporated in New York State in May of 1957. The majority owner was Don Steeb and the minority shareholders were the Gillette brothers who provided the necessary financing. These were not the same Gillettes who made razor blades but their fabrication business did most of the prototype work for Haloid Co. which became Xerox Corporation.

Don Steeb was one of the most trusted names in the business. A memorable example of how he earned this trust was when a test plane controlled by one of the first proportional systems (including Steeb servos), went out of control and crashed in a corn field. Steeb was in charge of this test flight and could have easily blamed the pioneer proportional radio since all of the pioneer systems had well known reliability problems. No one would have ever known better. Instead, he immediately took responsibility and announced the cause of the crash: “of all things, the elevator servo had failed”. Actually, one of the elevator servo electrical components had failed, not anything Steeb made or designed.

Here is a picture of Don Steeb and his Bramco reed system from the January 1961 issue of A.M.

Second Generation Servos

Here are the prototype second generation Atlas servos:

These servos were built to test the new smaller Uniperm motors, only 5/8 inch in diameter. Steeb flew this 4 servo prototype tray in 3 airplanes using the above Bramco reed equipment. The two smaller servos were positionable units with Siemens/Falhauber Micro Mo motors. The Micro MO motors were being tested to see if their delicate internal gearing could withstand engine vibration. They passed, and were later used in proportional servos requiring sensitive motors with low voltage starts. They were not used in regular Steeb servos, however, due to their much greater cost and weight. Here is the inside view of the 2nd generation prototype showing its new, orange colored Uniperm motor.

With these much smaller motors the overall size and weight of the second generation servos was reduced substantially. The weight dropped from three ounces to two. In addition to the use of smaller motors and aluminum (instead of brass) gears, in the production servos small additional weight reductions were achieved by refinements like a snap-on cover instead of a separate bracket and metal screw to retain it and the wiring.

Compared to the old servos, the power and current drain of the second generation servos were nearly identical, despite the weight reduction. Other improvements in the second generation include a one piece “U” shaped chassis and easier assembly.

Here are two-generations of servos side-by-side for comparison. Externally note the smaller size and darker blue finish. Internally note, the orange Uni-Perm motor and aluminum gears.

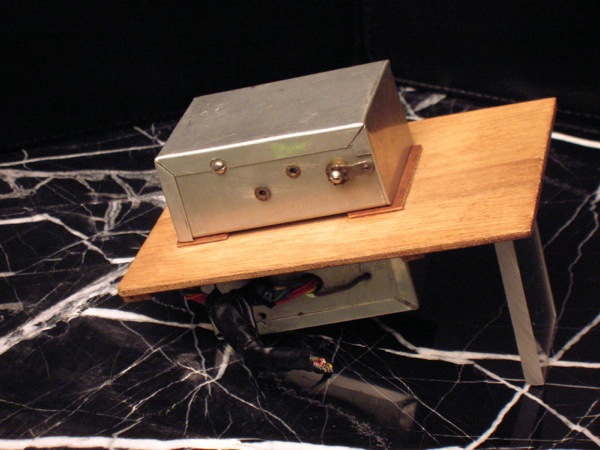

Here is Steeb’s prototype relayless unit. This is the first servo assembled with all the components that would be used in the production relayless actuators. Don was particularly proud of the neat layout of the electronics on the PC board.

Here is the Steeb product brochure around the time of the second generation servos.

Here is a second generation multi-servo (not proportional) in Sampey’s gold colors which used one of the left-over gold anodized cases after Steeb no longer made Sampey proportional servos:

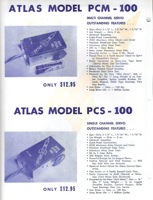

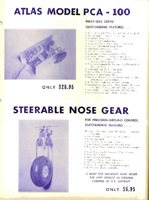

For more information on Don Steeb Inc. and its products, including the “Lightening” servo, later proportional servos and non-electronic products like steerable nose gears, see Steeb section.